While cooperating with Europe´s leading filter media manufacturers, the optimal filter material for dedusting your project is determined and applied accordingly. Towards this end, particularly needle felts made of synthetic fibres such as polyester, polypropylenes, polyacryl nitrite and polyphenylene sulphide purify the air. The filter bags consist of Teflon or Aramid if they have to cope with higher gas temperatures. Given temperatures ranging above 260°C, the application of fabric bags made of stainless steel or ceramic is possible for dedusting. Gaseous toxic materials are absorbed from the exhaust gas with the help of additives and separated as a solid substance in the DFT bag jet filter.

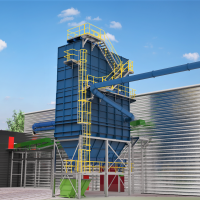

Filter bags with diameters of 120 or 150mm are installed in the modularly designed deduster chambers. The cleaned dust collects in the funnel or tub from where it is removed. Large maintenance doors on the filter ceiling with a counterweight make it easy to access the deduster´s clean gas chamber. The filter bags and supporting baskets are installed and removed at the clean gas side. The filter bags are attached to the bag carrier by means of snap rings and then sealed. The blow pipes fixed above the filter bags can be easily assembled thanks to simple plug connectors with O-ring gaskets.